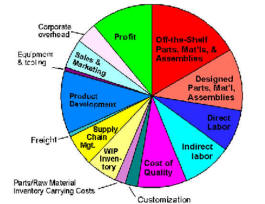

SELLING PRICE BREAKDOWN

(Figure 6.3 in firsts of second editions of DFM

book)

PROGRAMS THAT REDUCE SPECIFIC COSTS

HALF COST PRODUCT DEVELOPMENT

This is the only course that will show product development teams how

to design products to sell at half the selling price. Specifically, the

course will show how to achieve the following cost reductions to 1/N

of the previous state, followed by links to “how to” articles.

1/2 the project development budget,

in 1/2 the time : See the white paper:

http://www.design4manufacturability.com/concurrent-engineering.htm,

which includes vendor/partnerships:

http://www.design4manufacturability.com/vendor-partnerships.htm

1/2 the concept/architecture cost with

simplified concept breakthroughs, which is

important because the concept/architecture determines 60% of product

cost, as shown, with two generic examples, in the next article link.

Customized workshops will explore specific

design project opportunities:

http://www.design4manufacturability.com/designing_low_cost_products.htm

1/2 the assembly, labor, and

processing costs. See DFM article:

http://www.design4manufacturability.com/DFM_article.htm

1/2 of the quality costs. See the

Design in Quality article:

http://www.design4manufacturability.com/design_for_quality.htm

and increase savings to::

1/3 of the quality cost doing Design

in Quality AND Avoiding Cost reduction after Design:

http://www.design4manufacturability.com/cost_reduction.htm

1/3 of the Indirect

labor costs (fire-fighting, change orders); See comparison

timelines at:

http://www.design4manufacturability.com/half-the-time.htm

1/10 of material

overhead for standard parts based on surveys of Procurement

managers:

See opening page of Chapter 5:

“Standardization” in the definitive book on Design

for Manufacturability

1/10 of raw materials inventory

cost using:

Spontaneous Supply Chains,” Chapter 7,

in the 512

page BTO book which starts with a 60 page Summary

1/10 of work-in-process (WIP)

inventory* Cost, which can cost more than profits! See:

“Design for Lean and Build-to-Order:” Chapter 4 in

the author's DFM book, now translated into Chinese

1/10 of finished goods

inventory* Cost using Build-to-Order: See:

http://www.build-to-order-consulting.com/ or

Build-to-Order & Mass Customization,

the most thorough book written on Build-to-Order

SUMMARY OF 9 COST CATEGORIES

1/2 the project development budget

1/2 the concept/architecture

cost

1/2 the assembly, labor, and processing costs

1/2 of the quality costs

1/3 of the quality cost AND

Avoiding Cost cutting

1/3 of the Indirect labor costs

1/10 of material overhead for standard parts

1/10 of raw materials inventory cost

1/10 of work-in-process (WIP) inventory* Cost

1/10 of finished goods inventory* Cost

If your company or clients have high overhead charges, don't let these

excessive overhead charges burden your design project. Instead, spin

it off as a

"profit-and-Loss " center (see book section

.4.1.4 to get "Skunk-Works"

protection from excessive overhead

charges without needing a separate facility.

A Case Study in Appendix

A.1.3 A cites a 30% price Advantage

for an industrial equipment because their product was the only

product built in ait in a "focused factory" and their more

expensive copetitor still build everything they ever built!

This page presents a compelling

case for a quick financial return from momdist investment

providing nothing counter-productive gets in the way. If so, find

out how to identify and overcome whatever is Conter-Productive

page.

The very first

step may be to start with a few hours of thought-leader

consulting

to help formulate strategies and implementation

planning.