|

It is Time to Learn

New Ways to Design & Build

and Stop

doing what gets in the Way!

Examples below on

controlling machine functions, low-cost,

high-speed feeders, & ultra-low cost solar mirror drives.

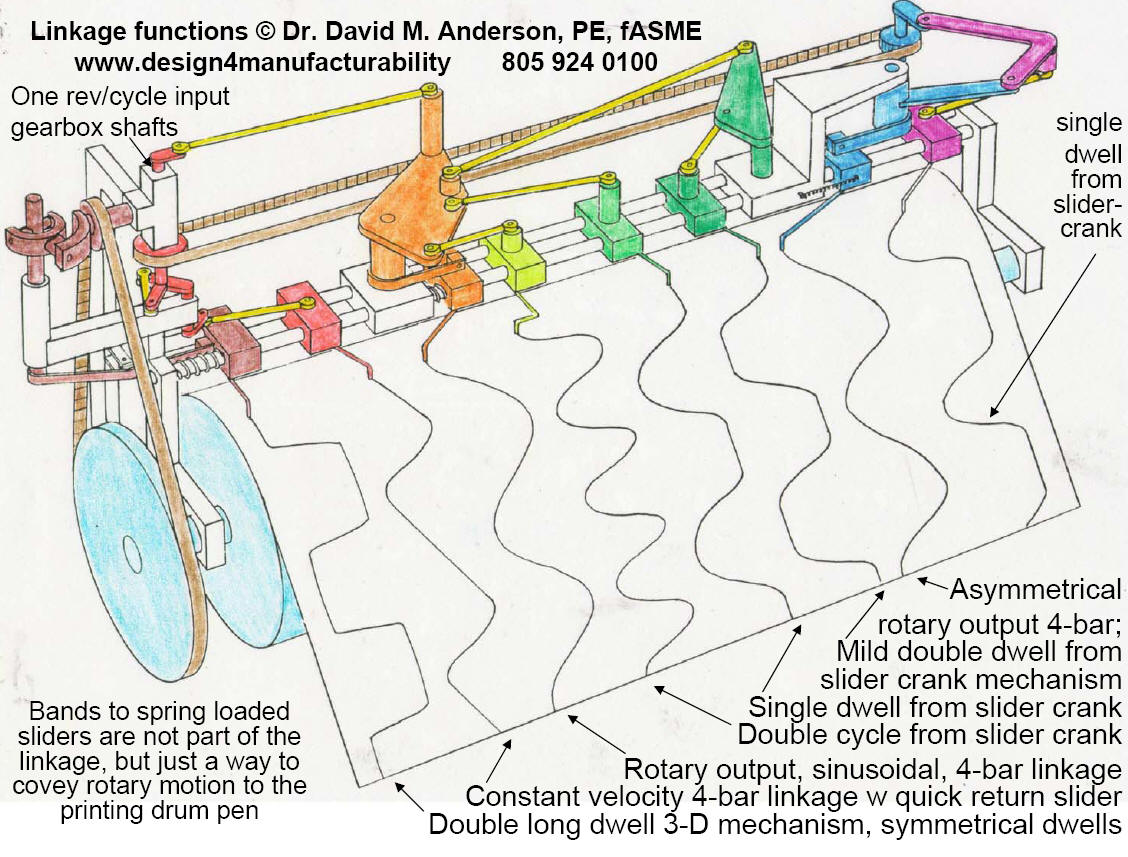

In addition to his expertise showing companies how to design

machinery for manufacturability, Dr. Anderson is also an expert in designing

linkages to generate motion functions for low-cost control of repetitive

functions. To illustrate the many functions that can be generated by

linkages, he created the following model that plots out many functions from the

illustrated linkages:

Motion Control with Linkages

Linkages provide a low-cost way to control repetitive machines. They can be

driven by any shaft rotating at one revolution per cycle. Many repetitive

machines have one of these shafts somewhere. Controlling machines with linkages

will ensure the:

Lowest Possible Cost. Linkages consist of a crank mounted on an input

shaft, driving a coupler link (usually a tube with rod end pivots on each end)

that drives an output crank. This will cost less than cams and a lot less than

computer controlled servo mechanisms or robots, either of which would be an

overly expensive overkill to .control simple repetitive motions.

Cleanest possible mechanism. Linkages are clean, open, run without

lubricants, and will not contaminate products or be affected by dirty

environments. They do not have to be enclosed to keep lubricants on cams or keep

liquids out off or electronic controllers and associated power and signal

cables.

This cleanliness makes linkage controls perfect

for food processing, pharmaceuticals, and for semiconductor fab clean rooms. In

fact, Dr. Anderson has designed ultra-clean wafer handling mechanisms that use

non-pivoting flexing bearings near semiconductor wafers. He has also designed

linkage-driven food processing to satisfy FDA cleanliness requirements.

This replaced an painted machine that was lubricated with oil and grease

with an all stainless-steel machine that was open enough to hose down and fully

inspect. It even had nozzles mounted on its pressurize frame!

Easy to build. Linkages are very easy to fabricate and assemble by

low-skilled labor. First of all, the input shaft may already be in the product

architecture as a gearmotor shaft or a gearbox shaft, or a two-shaft gearbox

would be expanded to three or four.

The input crank can be made from bar stock and be

bolted to an off-the-shelf shaft collar. The coupler link would most likely be

an internally threaded tube with off-the-shelf rod-ends or ball joints threaded

and locked to each end. The output crank may just be an arm rotating protruding

from the controlled member or the output crank would actually be the

controlled member, which would be guided and supported by the linkage (next

point).

Motion guidance. Linkages can guide and support parts or grippers

through 3-dimensional space. This would obviously be less expensive and easier

to build than separate systems for to (1) support the load on the moving

member and (2) control the motion, with more expensive cams or computer

controlled actuators.

Example # 1: Complex food processing machine controlled entirely by linkages. In order to satisfy

increasing FDA pressures for food processing cleanliness, Dr. Anderson

designed

linkage-driven machine that removed the pits from peaches, which was known as

the “Clean Pitter.” The drawing at the right, from Patent # 4,380,953, shows the

various linkages that would: orient the peach, grip it, transfer it into a pair

of blades, close the blade to grip the pit, and rotate rubber grippers in

opposite directions thus cutting the peach in half – at 90 per minute.. Since

this was a redesigns for cost, speed, and cleanliness, it preserved the “crown

jewels” of peach pitting that was refined over decades, whose motions were

guided by greased steel and controlled by a “geneva” (indexing) mechanism in an

oil bath over the food zone. This effective process is known as

commercialization that Dr. Anderson also teaches. See:

http://www.halfcostproducts.com/commercialization.htm . designed

linkage-driven machine that removed the pits from peaches, which was known as

the “Clean Pitter.” The drawing at the right, from Patent # 4,380,953, shows the

various linkages that would: orient the peach, grip it, transfer it into a pair

of blades, close the blade to grip the pit, and rotate rubber grippers in

opposite directions thus cutting the peach in half – at 90 per minute.. Since

this was a redesigns for cost, speed, and cleanliness, it preserved the “crown

jewels” of peach pitting that was refined over decades, whose motions were

guided by greased steel and controlled by a “geneva” (indexing) mechanism in an

oil bath over the food zone. This effective process is known as

commercialization that Dr. Anderson also teaches. See:

http://www.halfcostproducts.com/commercialization.htm .

The result was a low-cost, all stainless

steel machine that could easily be cleaned with its own nozzles tapped into its

pressurized frame! Since the linkage mechanisms were lighter and stronger, the

machine ran 50% faster.

To see a PDF brochure of the current version,

click on the "Clean Pitter II," link at the lower right of:

http://www.atlaspacific.com/#!peach-pitter/c6ic . (Historical

footnote: Dr. Anderson worked his way through college as a cannery mechanic

working on Atlas Pacific food processing machines.)

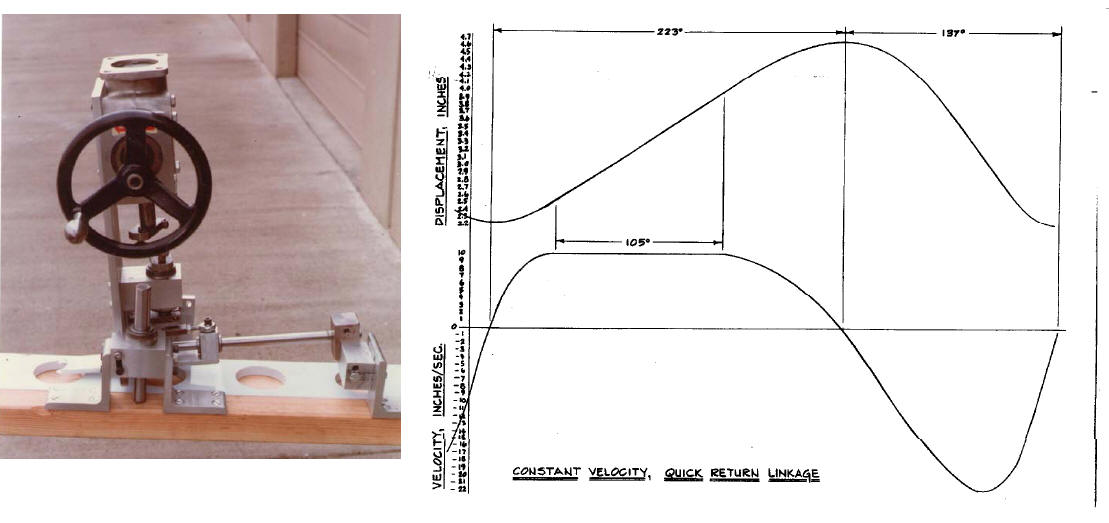

Example # 2: Quick-return constant-speed feeder. Dr. Anderson designed an

inexpensive 6-bar feeding linkage to drive a pusher to feed a scented pad into a

“stick up” product. In order to align the pad with the base part (which was

moving along a conveyor belt), the linkage had to push the pad at a constant

velocity, as shown in the velocity profile below. The linkage also had to return

quickly to get ready for the next stroke.

Like most machine control linkages,

the input is a one revolution/cycle input shaft, which, in this case, was in

sync with the conveyor speed. The top graphic shows a kinematic layout of

the 6-bar linkage pushing the symbol for a sliding member. The photograph

shows the scale mock-up linkage a hand crank as the input and a simulated

conveyor pockets.

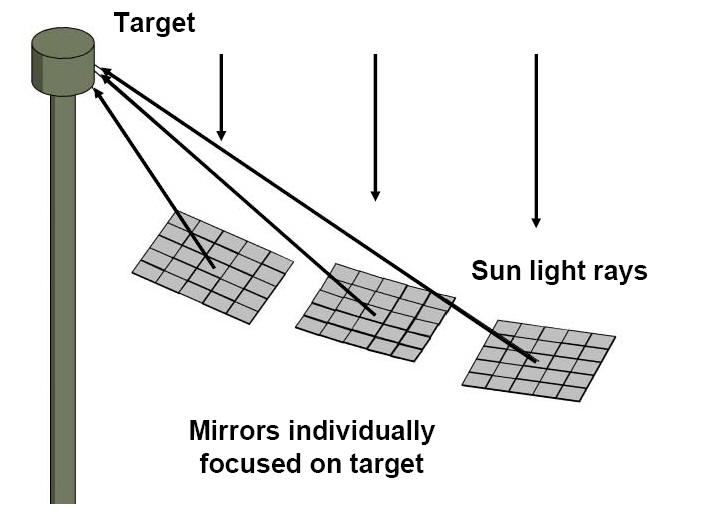

Example # 3: Linkage coupling of mirrors for ultra-low-cost

mirror guidance and 25 times better focus!. Conventional Concentrated Solar Power (CSP) power

plants use up to 350,000 “heliostat” mirrors that reflect sunlight onto a

tower-mounted target. Currently, each of these mirrors has two motors,

two gearboxes, two sets of sensors, and a computer to constantly correct both

axes all day. So a large solar field will have up to 700,000 of

these expensive control systems!

Dr. Anderson has

proven that an ultra-low-cost linkage system can couple arrays of

heliostat mirrors with low-cost linkages. This has not been done before because

no one has yet figured out how mechanically couple heliostat mirrors, since each

mirror must go through its unique daily path to reflect sunlight to a stationary

tower throughout each day. The field would thus consist of low-cost

mass-produced mirror assemblies. . The adjacent figure shows a close-up of

three coupled heliostats (with coupling linkages not shown) that individually reflect sun light at the target.

Further, focusing sunlight on the

tower can be improved 25 times!

Flat mirrors reflect un-focused light. All heliostat mirrors aim

their center at the target, but if the mirrors are flat, only the center is focused

at the target, and the rest of the sunlight shines above, below, and to the

sides of the target. This is because sunlight rays are parallel and flat mirrors

will reflect parallel sunlight rays. For instance, the outer edges

of 10 foot wide mirror will miss the target by 5 feet on each side!

Focused mirror facets can be 25 times better

focused. Sunlight focus can be improved 25 times if the heliostat consists of, say,

25 facets, each continually aimed at the target. In the above

illustration, the center mirror array shows all 25 mirror facets individually

aimed at the target, compared to the adjacent mirrors, which are

flat for a visual comparison.

Individually focused facets have been proposed

for solar furnaces (which can reach up to

3,500 oC) to replace large two-stage mirror systems (a tracking heliostat aimed at a

large fixed

parabola) with a single focusing heliostat that is focused

directly on the ultimate target. However, conventional design practice requires an extra 8 to 24

drives per heliostat. But even compromise attempts, like permanently angled

facets, won’t work on current heliostat designs that have an elevation axis

mounted over an azimuth (compass direction) axis, which rotate the mirrors

throughout the day. So, optimal

joint ordering, which is the first step in robot design, can provide (a) highly

focused mirrors and (b) stronger joint pivots.

Fortunately, Dr. Anderson can also apply

his linkage expertise to continually focus 24 “slave” mirrors on the target

throughout the day.

This brings solar furnace heat

and temperatures (UP TO 3,500 oC)

to solar power at ultra-low cost and weight.

This will be especially valuable for

generating the most heat and highest temperature for industrial processing or

heating large buildings and smaller, more compact mirror fields, where focus is

even more important. Further, larger heliostats will be possible

because (a) all mirror facets will be focused on the target (regardless of

heliostat size) and (b) structures can be stronger after getting away from an

elevation axis on top of an azimuth axis rotating on top of a pole,, which,

usually have both axes converging on a weak multi-ax-s bearing.

For Concentrated Solar Power,

(a) better focus can allow

heliostats to be closer to the tower and (b) more concentrated sunlight needs fewer

heliostats, thus resulting in more compact fields that will cost a lot less and need less land with less

permitting challenges. Further, this much greater focus can make solar

power much more feasible in northern climates and still reflect enough light to

be feasible. This, and the smaller land requirements would enable solar

replacements for fossil fuel burners in existing power plants, even in northern

climates on small or hilly sites.

These heliostats would not need field testing to verify the abovementioned

focus and functionality, since all the parts would be built on CNC machine tools

with all dimensions fabricated at +/- .001" accuracy, which is routinely

accomplished by these automated machine tools.

See how this fits into the big picture in the new white paper: "Half Cost

Concentrated Power" at:

http://www.halfcostproducts.com/half_cost_solar.html

Note that this sophistication should not to be confused with "ganged mirrors"

that bolt several mirrors onto a parabolic frame or four-bar-linkage "coupling,"

of identical frame pivots, all of which will miss the target because every

mirror in a heliostat field must be individually focused precisely as

described above.

Example # 4: Elevating wheelchair. For Dr. Anderson’s thesis project,

he designed and built a wheelchair in which linkages guide and support a

quadriplegic in many positions for better comfort and to improve indoor mobility

and driving. In the illustration at the right, from patent # 3,882,949.

Figure 1 shows the powered wheelchair in the typical position.

In Figure 2, the long ball-screw actuator (behind the

back rest) elevates the seat, while pulling in the feet and narrowing the

wheelbase to be able to access high kitchen cabinets without needing leg

clearance below, which is a common problem with all other wheelchairs.

Figure 3, the seat lowers and legs extend to the

“go-cart” position for stable running on slopes and for driving in a sedan with low ceilings. Dr.

Anderson also designed and built a scale model of the concept for a

linkage-based loading mechanism which would lift the wheelchair, in the low

position, and pace it in either driver or passenger seat of a large sedan.

In the low position, the back rest can recline to redistribute body weight to

relieve and protect the skin.

The photograph below shows the first six prototypes at a

range of seat heights from the fully reclined low position to the highest

position (corresponding to Figure 2) with the foot rest pulled in to enable

reaching above kitchen counters. As the seat raised, the wheelchair width

narrowed four inches for improved indoor maneuverability.

Dr. Anderson can show companies how to

incorporate these techniques into their products with

seminars and workshops or do design studies working with company engineers

to finish the implementation.

These are the general principles. Pass

around this article or URL to educate and stimulate interest

All of these

principles on DFM can be included in

your customized

class and workshop on DFM

or

the

Most Effective Product Development class

If you want to discuss Linkages & Mechanisms

by phone ot e-mail, fill out this form:

In customized seminars and

webinars, these principles are presented in the context of your

company amongst designers implementers, and managers, who can all discuss

feasibility and, at least, explore possible implementation steps

In customized workshops, brainstorming sessions

apply these methodologies to your most relevant products, operations, and supply

chains.

Call or email

about how these principles can apply to your company:

copyright ©

2021 by

David M. Anderson

Book-length web-site on Half Cost Products:

www.HalfCostProducts.com

[DFM Consulting] [DFM

Seminars] [DFM webinars]

[DFM Books] [Credentials]

[Clients] [Site Map]

[DFM article]

[Half Cost Products site] [Standardization

article] [Mass Customization article]

[BTO article] [Rationalization

article]

|